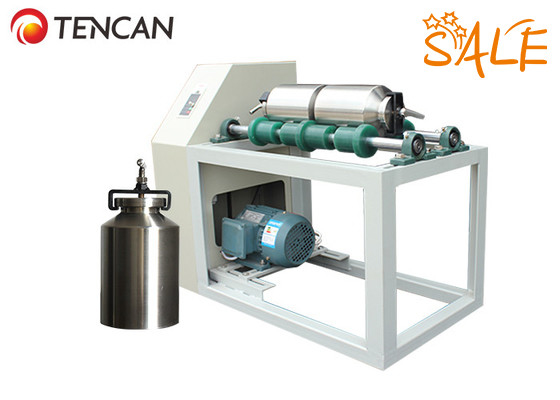

2*5L Horizontale Rolpotmolen Micron Poeder Slijpen Mengen voor Laboratorium/Kleine Batch Productie Spanning 220V-50Hz of 110V-60Hz

Productdetails:

| Plaats van herkomst: | Hunan, China |

| Merknaam: | TENCAN |

| Certificering: | CE ISO |

| Modelnummer: | GQM-2-5 |

Betalen & Verzenden Algemene voorwaarden:

| Min. bestelaantal: | Eén set |

|---|---|

| Prijs: | Onderhandelbaar |

| Verpakking Details: | Carton+Foam |

| Levertijd: | 3-7 werkdagen na ontvangst van de volledige betaling |

| Betalingscondities: | T/T, Western Union |

| Levering vermogen: | 200 stuks per maand |

|

Gedetailleerde informatie |

|||

| Naam van het product: | De horizontale Molen van de Broodjeskruik | Model nr.: | GQM-2-5 |

|---|---|---|---|

| Werksposities: | 2 Posities | Totaal volume: | 10 liter |

| Maximale capaciteit: | 3.33L | Rotatiesnelheid: | 50-410 t/min |

| Spanning: | 220V-50Hz of 110V-60Hz | Kracht: | 0.37 kW |

| Markeren: | 2*5L Horizontale Rolpotmolen |

||

Productomschrijving

Technische Parameters

| Technische Parameters van Rollende Pot Laboratorium Kogelmolen | |||||

| Categorie | Afmetingen/WT (mm) |

Modelnummer | Motor Vermogen(kw) |

Spanning | Rotatiesnelheid (rpm) |

| 2 werkstations | 950*480*685mm/59kgs | GQM-2-5 | 0.37 | 220V-50Hz/60Hz | 50-410 |

| 1130*550*690mm/80kgs | GQM-2-15 | 1.1 | 220V-50Hz/60Hz | 40-365 | |

| 13506550*690mm/92kgs | GQM-2-20 | 1.5 | 220V-50Hz/60Hz | 40-365 | |

| 4 werkstations | 950*660*690mm/70kgs | GQM-4-5 Enkele Laag |

0.75 | 220V-50Hz/60Hz | 50-410 |

| 950*480*870mm/92kgs | GQM-4-5 Dubbele Lagen |

0.75 | 220V-50Hz/60Hz | 50-410 | |

| 1130*800*690mm/95kgs | GQM-4-15 | 1.5 | 220V-50Hz/60Hz | 40-365 | |

| 1350*820*690mm/122kgs | GQM-4-20 | 2.2 | 380V-50Hz/60Hz | 40-340 | |

| 8 werkstations | 950*660*960mm/106kgs | GQM-8-5 | 1.5 | 220V-50Hz/60Hz | 50-410 |

| 1130*800*690mm/152kgs | GQM-8-15 | 2.2 | 380V-50Hz/60Hz | 40-365 | |

Accessoires van Rolmolen Potten & Ballen

Naast rollende kogelmolenmachines leveren we allerlei soorten rolmolenpotten, zoals roestvrijstalen molenpotten, zirconia molenpotten, alumina keramische molenpotten, nylon molenpotten, PU molenpotten, PTFE molenpotten, enz. Verder leveren we ook roestvrijstalen molenballen, zirconia molenballen, alumina molenballen, agaat molenballen, wolfraam molenballen, etc.

![]()

| Aanbeveling voor passende oplossingen over molenpotten & materialen | |

| Categorieën van Materialen | Aanbevolen Molenpotten |

| Grond en andere materialen die geen onzuiverheden mogen bevatten | Agaat molenpot |

| Metaal & non-metaal materialen die geen onzuiverheden mogen bevatten | Zirconia molenpot |

| Materialen met hoge hardheid zoals diamant, wolfraamcarbide | Wolfraamcarbide molenpot |

| Sterke toevoegingen & alkali materialen of andere materialen bij hoge temperatuur | PTFE molenpot |

| IJzererts materialen met lagere gevoeligheid voor onzuiverheden | 304 Roestvrijstalen molenpot |

| Pigment of andere materialen met een later proces bij hoge temperatuur | Nylon molenpot |

| Aluminium materialen zoals keramisch glazuur | Korund molenpot |

| Elektronische materialen zoals lithium batterij | Polyurethaan molenpot |

| Gemakkelijk geoxideerde materialen of sommige speciale materialen die moeten worden beschermd onder een speciale atmosfeer. |

Vacuüm molenpot |

![]()

| Referenties over slijpmedia & materialen | ||

| Materialen van Slijpmedia |

Hardheid (Mohs) |

Eigenschappen |

| Zirconia Ballen | ≥9.0 | Super slijtvast, zonder enige onzuiverheid, corrosie & hoge temperatuurbestendigheid. |

| Roestvrijstalen Ballen | ≥6.0 | Slijtvast, algemene corrosiebestendigheid, hoge temperatuurbestendigheid. |

| Agaat Ballen | ≥7.0 | Super slijtvast, gebruikt voor medicijnen, voedsel en andere materialen die niet met metaal verontreinigd mogen worden, corrosie en hoge temperatuurbestendigheid. |

| Alumina Ballen | ≥8.5 | Slijtvast, corrosiebestendigheid en hoge temperatuurbestendigheid. |

| Wolfraamcarbide Ballen | ≥9.0 | Super slijtvast, zonder enige onzuiverheid, corrosie & hoge temperatuurbestendigheid. |

| Passende Oplossingen voor Molenpotten & Ballen | |||||

| Items | Agaat Ballen | Alumina Ballen | Roestvrijstalen Ballen | Zirconia Ballen | Wolfraamcarbide Ballen |

| Agaat Molenpot | √ | ||||

| Korund Molenpot | ▲ | √ | ▲ | ||

| Roestvrijstalen Molenpot | √ | ||||

| Zirconia Molenpot | ▲ | √ | |||

| Nylon Molenpot | ▲ | √ | |||

| PTFE Molenpot | √ | ▲ | |||

| Polyurethaan Molenpot | √ | ▲ | |||

| Wolfraamcarbide Molenpot | ▲ | √ | |||

| √ betekent: meest geschikt ▲ betekent: geschikt | |||||